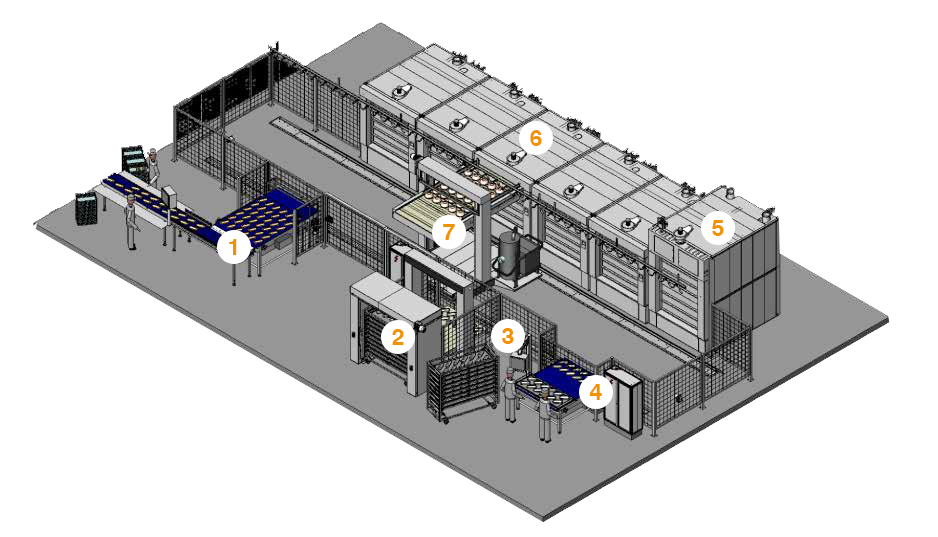

MATADOR

5. Prebaking oven – MATADOR® MDV:

- All around interior baking stone lining

- High baking chambers

- Extremely high temperatures up to 350 °C

- Storage heat of the stones allows baking with decreasing temperature

- Artisanal top quality as in a wood-fired oven

6. MATADOR® MDV ovens:

- Up to 8 MATADOR® MDV deck ovens possible

- Deck oven depth 2,000 to 2,400mm

- Deck oven width 1,200 and 1,800mm

- Burner on the back of the oven

- Oven maintenance from the rear during operation of the entire OBER plant

- MATADOR® baking result guaranteed

- Energy-efficient thanks to ZYKLOTHERM® heating system