Bread roll lines

Convenient bread roll systems for gentle machine forming and optimal automatic dough moulding. For individual small bakery items with maximum quality from artisan production: Dough pieces with perfectly preserved structure and strong gluten network through intensive moulding and singularly good shape.

FORMPROFI Compact roll baking system

Hourly capacity: max 4,000 pcs

Weight range: 25 – 90 g

Product variety: stamped, round

MINIROLL Compact roll baking system

Hourly capacity: max 9,000 pcs/h

Weight range: 35 – 150 g

Product variety: long, round

SELECTA MODULAR Modular roll line

Hourly capacity: max 9,000 pcs

Weight range: 35 – 90 g, 150 g / via bypass

Product variety: stamped, cut, long, round

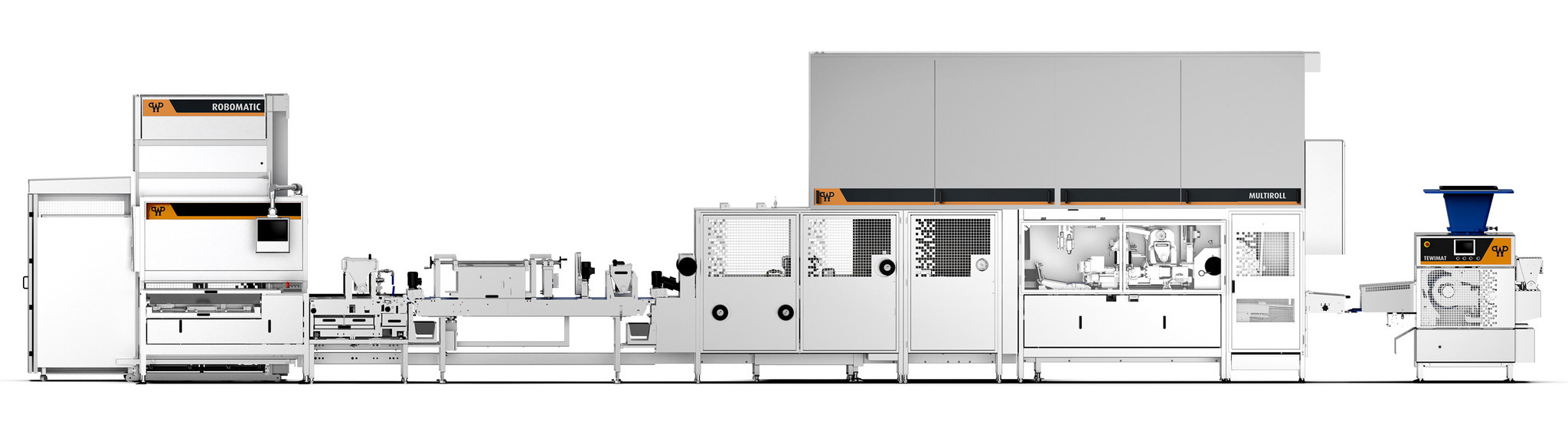

MULTIROLL Multifunctional roll line

Hourly capacity: on request

Weight range: 30 – 250 g

Product variety: round moulded, stamped, long-rolled, flattened, braided, wrapped, seeded

ROBOMATIC Automatic tray loading robot

Hourly capacity: 180 trays

Function: Automatic loading and unloading of trays

What’s new?

Stay up to date with the WP newsletter.

The finest craftsmanship

makes the bakery rolls so valuable

Creativity in the smallest space:

bread roll systems and dough formers for artisan bakers

Customers greatly value a nicely formed and moulded roll

The artisan shape of small bakery items conveys quality and value. However, bakehouses depend on the right tools to keep this process economically efficient for bakeries. Compact roll systems take over the monotonous part of broll production: forming, moulding, round-moulding, long-molding and stamping – reliable and in the smallest possible space.

Wachau rolls

Wachau rolls are rustic rose rolls made up with flour instead of the usual fat. A Wachau station works flour into the dough pieces particularly gently and carefully. This creates the rough surface typical of Wachau rolls – just like hand-rolled. Thanks to a servo motor that drives the remoulding station, the moulding process can take place very slowly, so that the dough structure is preserved, and rolls with beautifully pronounced crust break and appealing volume are produced.

Stamped rolls

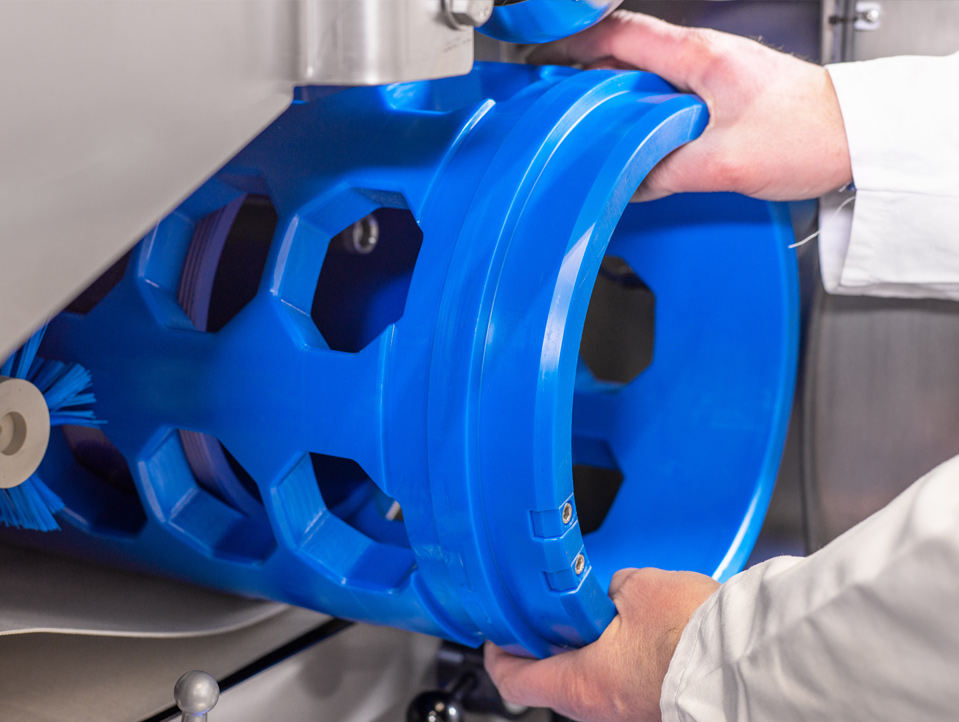

A revolver stamping head, equipped with standardized, partly interchangeable stamping tools, allows maximum flexibility for stamped products. In addition to standard stamps, such as Kaiser, rhombus, heart-shaped or Kringel, a revolver stamping head can optionally be equipped with a wide range of individual stamps. This allows for the production of truly unique items, such as rolls with the bakery’s initials. The creative choice of motives knows no boundaries.

Berliner

Green mode, e.g. for the production of Berliner dough pieces, is possible with direct depositing. This way, the dough pieces are transferred directly onto a depositing conveyor, thus saving time and bypassing the pre-proofing stage. Spreading belts are simply lowered by hand, so that the dough pieces run from the spreading belt onto a depositing conveyor, from where they are deposited onto boards, trays or Berliner boards in a depositing pattern stored in the program memory.

Automatisiertes Beladen und Entladen

von Dielen und Blechen

Der Beladeroboter ROBOMATIC übernimmt das Handling von Dielen und Blechen vor Kleingebäckanlagen und Brötchenanlagen.

Process solutions for small bakery items

in perfect craftsmanship quality

We are WP Bakery Technologies. We have been producing technical solutions for bakers for over 140 years. We design and build, install and service baking ovens as well as machines and process solutions for bakeries. Within the WP BAKERYGROUP we are the experts for dough dividers, moulding machines and roll systems with production volumes for artisan bakeries of up to 9,000 pieces per hour.

Dough dividing & moulding

A gentle dough dividing and moulding process is crucial for the high quality of end products. The task is to preserve the gluten network and the structure developed during moulding and dough resting time as completely as possible during automated further processing of the dough into perfectly shaped dough pieces.

Compact roll system for a wide variety of products

The demands on machines and systems are ever increasing, but not automatically so the space available in bakeries’ bakehouses or production halls. We offer various options for configuring your system exactly to your needs, so that you can make optimum use of the space in your bakehouse. Split version delivery is also possible as an option for some systems.

Modular roll lines for growing performance requirements

Responding to changing market requirements at any time, always keeping your product range attractive, and producing individual baked goods. Select the performance you need today. If your production increases, the system can be easily expanded in the future. The modular design: maximum flexibility for every need with a production volume of up to 9,000 pieces/hour and more.