Dough divider & roundmoulder

Reliable dough dividing and round-moulding machines for particularly gentle dough processing, maximum weight accuracy and flexibility due to a large weight range.

MULTIMATIC C Dough divider and round moulding machine

Weight range: 25 – 150 g

Rows: 4 till 6 rows (artisan)

Hourly capacity: max 1,500 pcs/row

Dough yield: up to 160

MULTIMATIC PRO Dough divider and round moulding machine

Weight range: 24 – 150 g

Rows: 4 till 6 rows (artisan/semi-industrial)

Hourly capacity: max 2,000 pcs/row

Dough yield: up to 160

MULTIMATIC VARIO Dough dividing & round-moulding machine

Weight range: 25 – 600 g

Rows: 1 till 5 rows (artisan/semi-industrial)

Hourly capacity: max 2,000 pcs/row

Dough yield: up to 160

TEWIMAT Dough dividing and round-moulding machine

Weight range: 28 – 310 g

Rows: 3 till 10 rows (industrial)

Hourly capacity: max 3,000 pcs/row

Dough yield: classic standard doughs up to TA 160

TEWIMAT SOFT Dough dividing and round-moulding machine

Weight range: 28 – 310 g

Rows: 3 till 10 rows (industrial)

Hourly capacity: max 3,000 pcs/row

Dough yield: soft, smooth and sticky doughs up to TA 170

TEWIMAT PLUS Dough dividing and round-moulding machine

Weight range: 28 – 600 g

Rows: 3 till 6 rows (industrial)

Hourly capacity: max 2,000 pcs/h/row

Dough yield: classic standard doughs up to TA 160, optional: soft, smooth and sticky doughs up to TA 170

What’s new?

Stay up to date with the WP newsletter.

Dough dividing and round-moulding machines

for artisan bakeries and industrial bread roll production

Designed for reliable, flexible and continuous use in the production of dough pieces for small bakery items in an enormous weight range from 24 g to 600 g. The range includes dough piece production solutions for artisan bakeries, semi-industrial bakery businesses as well as industrial production facilities.

What is the perfect dough preparation for rolls or other small bakery items?

Ideal mechanical dough processing resembles manual processing as much as possible. The result is a harmoniously round-moulded dough piece, in which the sensitive dough structures are preserved. Very high weight accuracy is achieved in the dividing process.

Bread roll systems, baking systems for small bakery items, and more

Our MULTIMATIC dough dividing and moulding machine is integrated in our compact bread roll systems. The TEWIMAT is often used as a head machine in industrial bakeries. Both types of head machine are also essential components of our baking systems for small bakery items. We offer various options for configuring your system exactly to your needs, so that you can make optimum use of the space in your bakehouse and produce the widest possible variety of products.

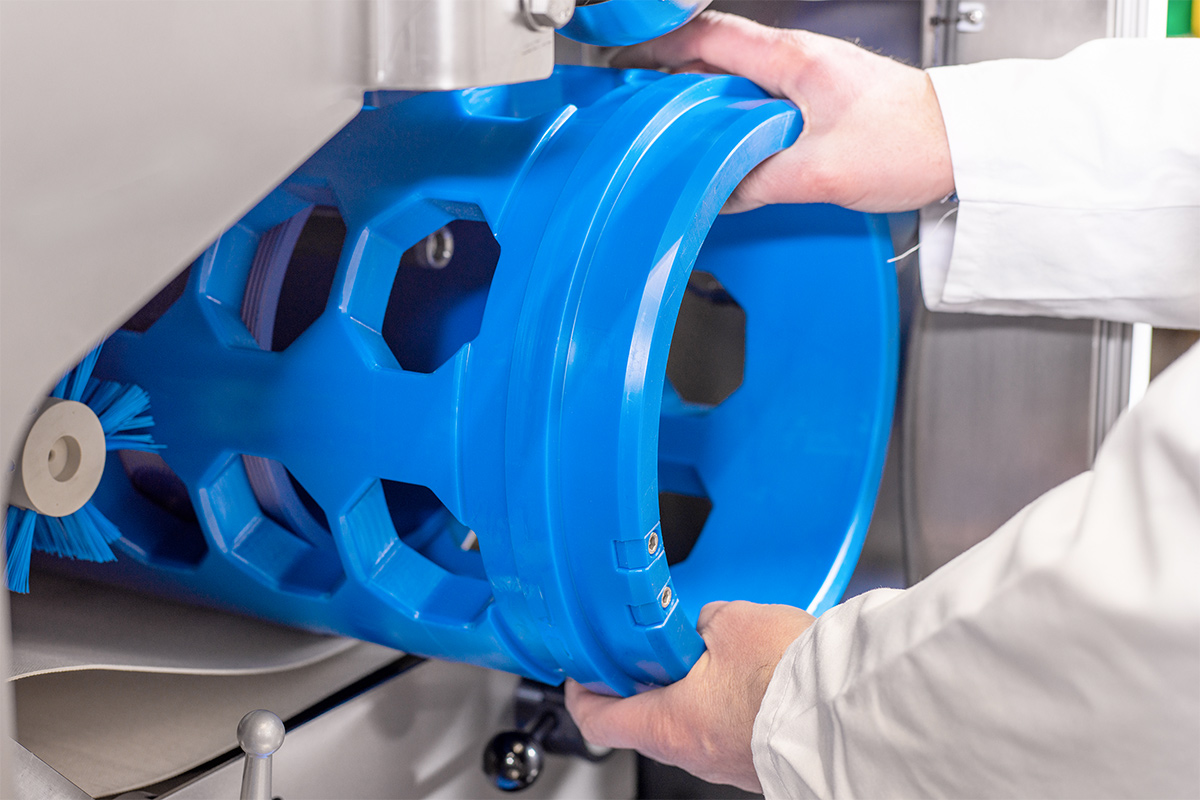

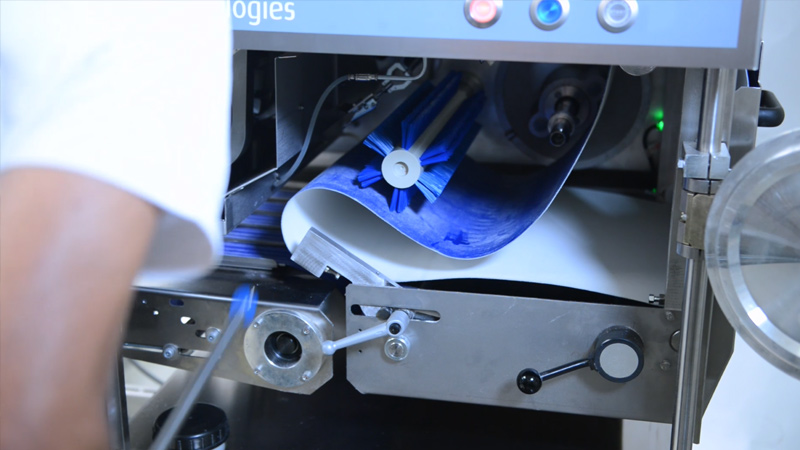

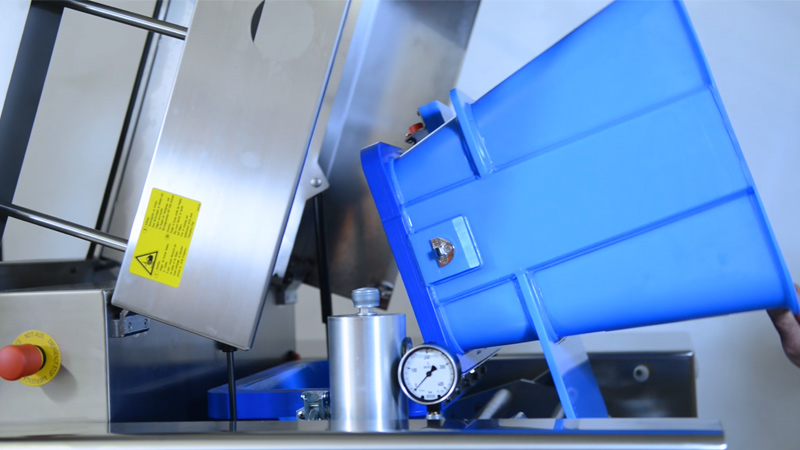

A clean affair: every version meets the highest hygiene requirements

All head machines are designed to be cleaned very easily, and therefore hygienically. All dough-handling machine parts are consistently separated from the drive components and all side panels can be opened, which provides for good accessibility. In addition, belts and dough-handling parts are for the most part kept in hygienic blue, so that contamination can be detected immediately. The surfaces are particularly smooth and have no edges, so that no dirt can accumulate in the first place.

Hygiene

Hygiene

Hygiene

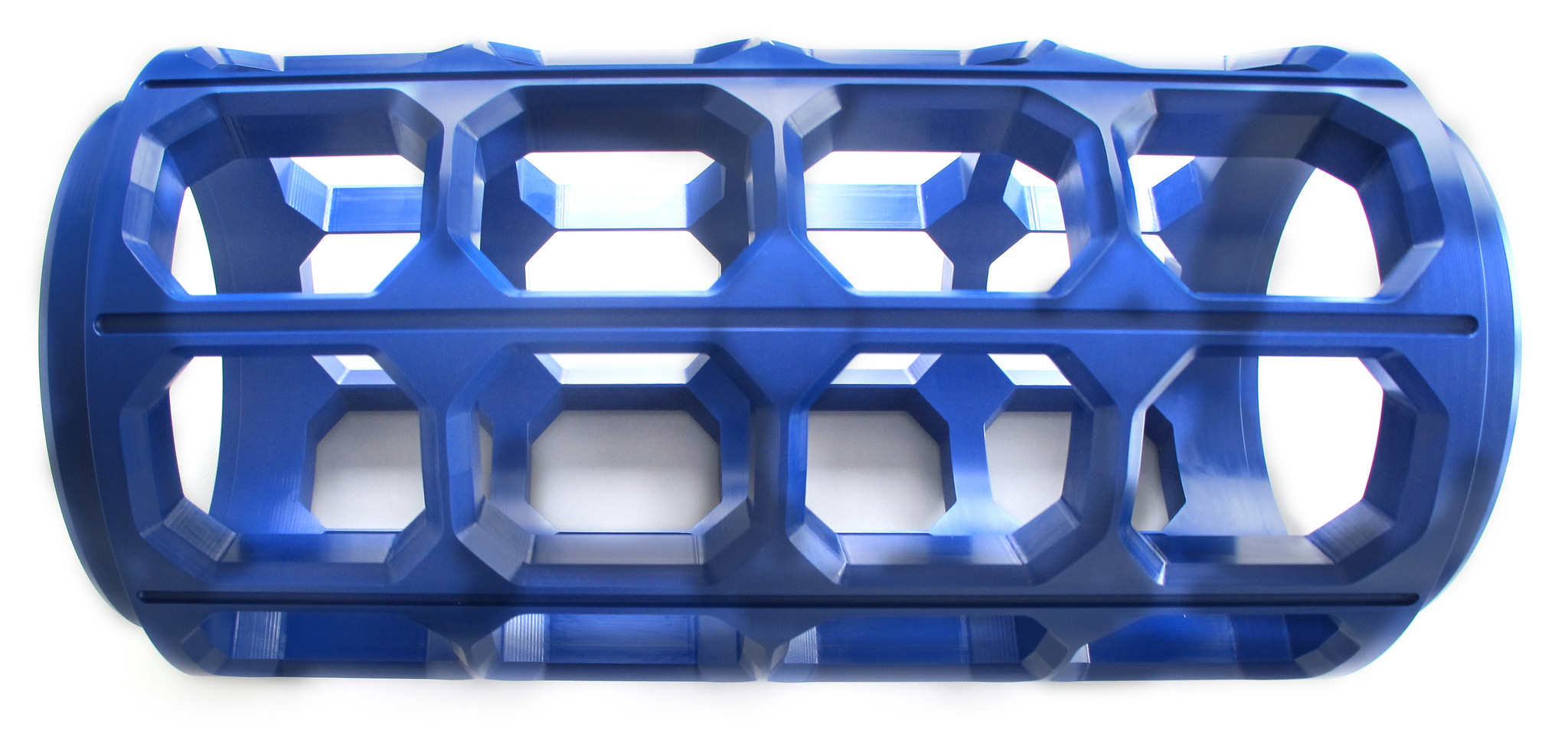

Maximum flexibility for a wide range of small bakery items

With the proven head machines of the WP MULTIMATIC and TEWIMAT series, your options are endless. The processing of all conventional roll dough in a weight range of 24 g to 600 g enables production of a wide variety of small bakery items. The maximum flexibility in terms of weight range and number of lanes is impressive. Thanks to the double piston system and the exchangeable chamber drums, changing the weight range only requires a few simple steps. Furthermore, the number of lanes can be changed in a very short time by simply rotating the measuring pistons; each lane can be blocked independently of the other.

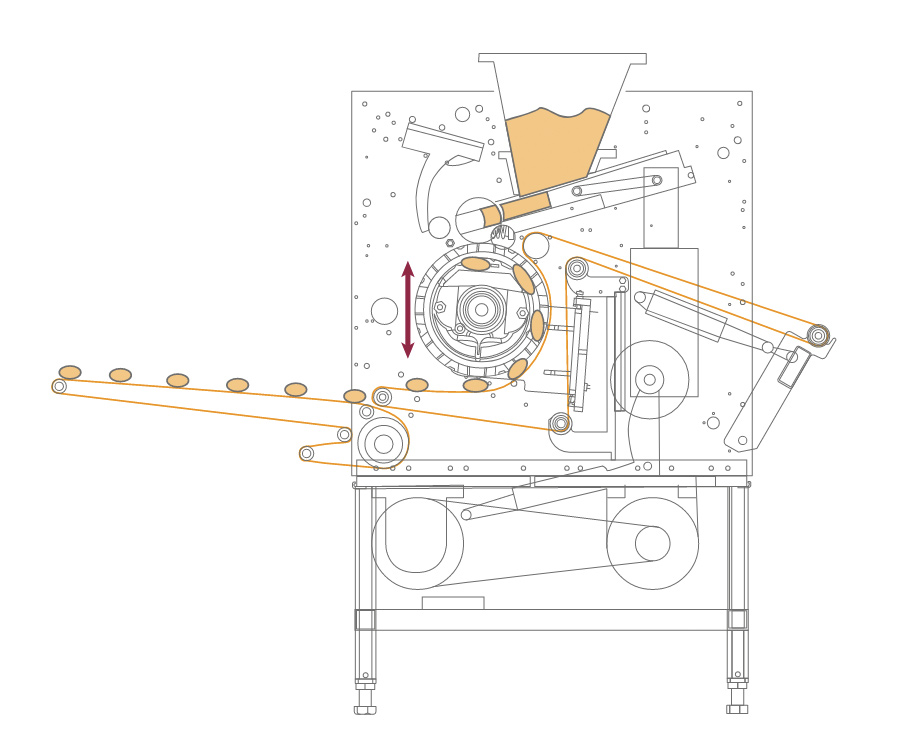

Technologies and methods for perfectly moulded dough pieces

With the proven suction divider technology, the integrated drum round moulder, the exceptionally long moulding path and the adjustable flouring, the head machine works with extreme gentleness on the dough and high weight accuracy. Employing innovative technologies and knowledge gained from many years of research, WP has succeeded in developing a new patented dividing system. It allows the free air contained in the conveying pistons to escape completely. This offers several benefits at once. Less force is required in the dividing process, since no more air has to be dissipated. This allows for lower filling pressures that divide the dough more gently. For perfect bread roll quality.

The TEWIMAT SOFT is unique when it comes to soft, long maturing dough. The patented mechanical design of its height adjustable moulding drive allows the dough pieces to be taken directly off the measuring piston. The conventional ejector shaft has been eliminated.

Our sales team will gladly answer all your questions.

![[Translate to Englisch:] Teigteiler und Wirkmaschine TEWIMAT SOFT für weiche Teige](/fileadmin/wpl/produktwelt/tewimat-soft/WP-Teigteiler-TEWIMAT-TEWIMAT-SOFT.jpg)