Bakery ovens and automation

We have been developing ovens for bakers for over 140 years. Our experience and process expertise from dough preparation to baking give you insight into the entire production process. This allows us to develop ovens that fit perfectly into your production and open up new possibilities for you. Production ovens from WP have been an investment in the future for generations due to their guaranteed long service life and energy efficiency.

A good oven is the heart and soul of the bakehouse

Every bakery is known and valued for the crumb, crispness and volume of their bakery items. Bakers are heavily dependent on a reliable production oven that never lets them down and produces identical quality day in, day out. Particularly consistent and repeatable baking results over decades provide the basis for building a loyal customer base, and are the essence of lasting business success.

Trust and reliability

The current development is very positive for consumers. You enjoy quality, variety and freshness. More than ever before. At the sales counter, it is hardly pure hunger that determines the success of the product, but rather spontaneous enjoyment. As a baker, you make a significant contribution to this development. Because you enjoy trust and offer reliability. Both by keeping your own recipes and by being open-minded to new products. In both cases, it is essential to meet the highest standards every day.

Perfect technology

What use are the tastiest recipes and the best ingredients if they can't be baked to the same quality day after day? Satisfied customers and economic success require two things: your professional qualifications and the best possible equipment. With this in mind, we see ourselves as a competent partner. For classic bakeries as well as for chain stores that have grown over time. Regardless of the size of the company, we offer customers the highest level of personal advice, precise planning, pioneering technology and sustainable support.

Knowledge and vision

We have the know-how to equip bakeries of all sizes precisely so that they can work efficiently and economically. How profitable they ultimately are is determined by each baker based on their personal strengths. What is very important is that the WP BAKERYGROUP is the only full-service provider in the world! Not only the ovens are designed, produced and installed, but also all the associated peripherals! The Made in Germany makes every MATADOR® a technically sophisticated and outstanding quality product. In short: We have been providing bakers with the basics for over a hundred years. Many thousands of them around the world build their businesses on it. The MATADOR® deck oven has been synonymous with perfect technology for six decades.

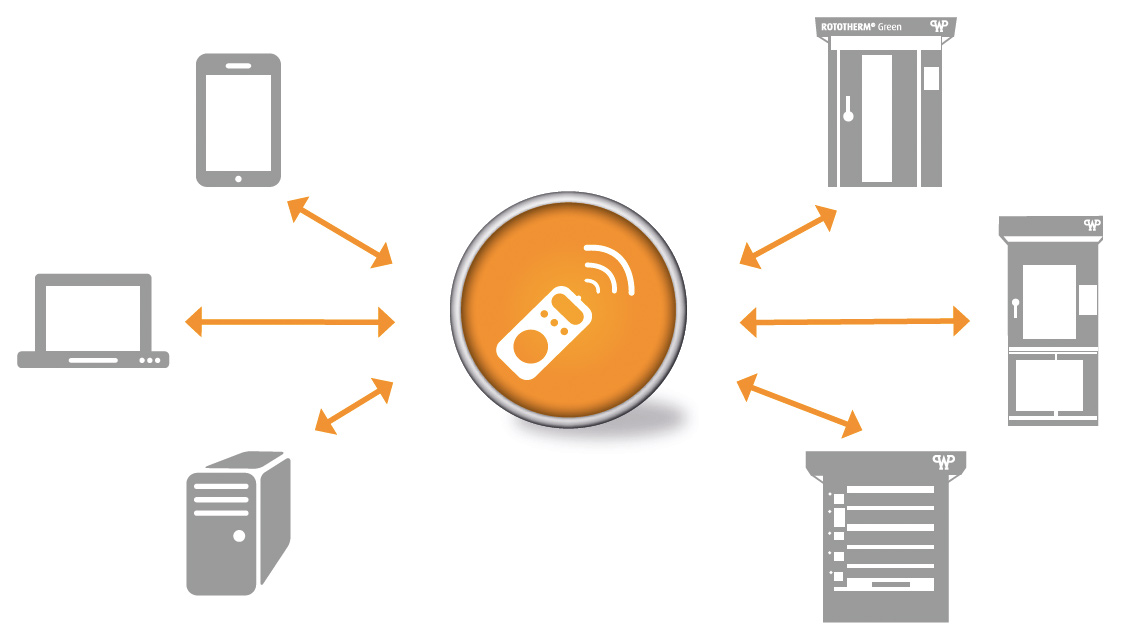

WP BakeryControl – the digital production management for monitoring, control, facilitated recipe entry and transparency

Networking ovens with WP BakeryControl: Control centre with beneficial automation for supervision, control and easier recipe entering.

Multi-deck ovens with heat recovery

Produce the best baking results energy-efficiently

Extremely uniform baking results repeatable at any time – and of course over a period of many decades. Every single one of our deck ovens has to meet this clearly defined requirements. Integrated heat recovery systems allow waste heat to be used effectively to save energy and reduce operating costs.

MATADOR Multi-deck oven

Baking area: 8.0 – 19.0 m²

Heated by: oil/gas/electric (convertible with electric heating cartridge)

Loading: manually

MATADOR MDE Multi-deck oven

Baking area: 11.5 – 17.28 m²

Heated by: direct electrical

Loading: manually

PELLADOR Wood-fired oven

Heating: directly pellet-fired

Baking area: 3.8 – 25.9 m²

Loading: automatable

WP RETHERM heat recovery powered by Ganzenmüller in action

The WP RETHERM heat recovery system powered by Ganzenmüller optimizes your oven system’s energy costs. The overall solution consists of smooth tube heat exchanger, control unit, storage tank, fresh air supply, flue and the connection to your heating and hot water installations.

Rack ovens with heat recovery

Produce the best baking results energy-efficiently

Energy saving at its best! Our rack ovens are utilized wherever large quantities of small baked goods are baked economically efficient to meet highest demands. Simple operation, efficient baking, and unmistakable results. Integrated heat recovery systems allow waste heat to be used effectively to save energy and reduce operating costs.

ROTOTHERM Rack oven

Baking area: 10.0 – 13.8 m²

Heated by: oil/gas/electric

Best-quality baking results with high energy efficiency

ROTOTHERM Heavy Duty Rack oven

Baking area: 20.0 – 22.0 m²

Heated by: oil/gas/electric

The heavy-duty worker among the ROTOTHERM series

ROTOTHERM Drive Through Rack oven

Baking area: 10.0 – 13.8 m²

Heated by: oil/gas/electric

The rack oven as drive through version or as hygiene lock

What’s new?

Stay up to date with the WP newsletter.

Why you are so important as a baker

Admittedly, people do not live by bread alone. But our diet is hard to imagine without bread. Today it is not just the creative combination of tradition and innovation that leads to new, popular baked products. At the same time, ever-increasing globalization ensures an exciting, limitless exchange of all recipes for success.

Excellent baking quality

Crisp, tender flaky crust, a nice volume, and a juicy crumb are what characterizes bakery products of superior quality. Excellent vapor performance of the oven is crucial in this context: consistent vapor creates juicy bakery products. Optimized air flow applies more energy on the dough pieces, shortens the baking time and makes your items particularly juicy. A particularly rich vapor increases the product’s volume, providing true delight both visually and in terms of flavor.

Economic efficiency through energy efficiency

The oven makes a crucial contribution to the success of a bakery, significantly determining the quality of the baked goods and the economic efficiency of your business. A smaller burner with reduced connected load and combined with an innovative heat exchanger, for example, is the “motor” of the ROTOTHERM®. Optimized technology that uses less fuel, and yet achieves excellent baking results at the same time.

The oven’s long service life

We have supplied the base for bakers for consistently high-quality bakery items for more than one hundred years. Thousands of professionals all over the world build their business on it. Due to the extremely long utilization period, the investment in a new MATADOR® is somewhat similar to an intergenerational contract. In the truest sense of the word. What the grandfather bought, even the grandson can continue to use in many instances. This is the pleasant and logical consequence of our intergenerational experience.

- Conversion to liquefied petroleum gas (LPG, propane/butane): This requires the mixing unit on the burner to be replaced, the piping to be changed and the burner to be readjusted.

- Conversion to liquefied natural gas (LNG): For this purpose, a liquid gas tank must be installed and connected to the burners.

- Conversion to oil burner: WP ovens can be operated with both gas and oil burners. Thus, conversion to oil burners is also always possible, but the burner must be replaced and an oil tank and piping must be installed.

- Conversion to electrical heating: WP offers electrical cartridge heaters that are geometrically adapted to the burners and can thus be inserted into the combustion chamber to replace a burner. Additionally, a suitably dimensioned cable must be installed. Since the required power is significant, it is essential to check whether the building connection is capable of providing this power. A factor of 3 should be calculated for energy costs compared to oil or gas.

Are you looking for advice on your options?

Get in touch

WP BakeryControl

The central software for your bakery

WP BakeryControl helps bakeries sustainably to increase efficiency and reduce costs: better control of the baking sequence in relation to capacity utilization, extended product shelf life, less scrap, and consistent quality thanks to stored recipes and automated machine control. Together with interested companies in the bakery trade, our specialist advisors examine the individual savings potential and possible steps to digitize production. Interested? Please contact us! Safe. Better. Digital.

Our sales team will gladly answer all your questions.