Vacuumcooler

VACUSPEED®

artisan

![[Translate to Englisch:] Vakuumkühlung VACUSPEED artisan [Translate to Englisch:] Abbildung der Vakuumkühlzelle VACUSPEED® artisan](/fileadmin/wpl/produktwelt/kuehlen/vacuspeed-artisan/WP-Vacuumkuehlung-VACUSPEED.jpg)

- Long-lasting crispness and stability of baked goods throughout the day

- Extension of Best-Before Date by up to 3 weeks

- Reduced energy requirement for crisping up products

VACUSPEED® the key to cost-effectiveness

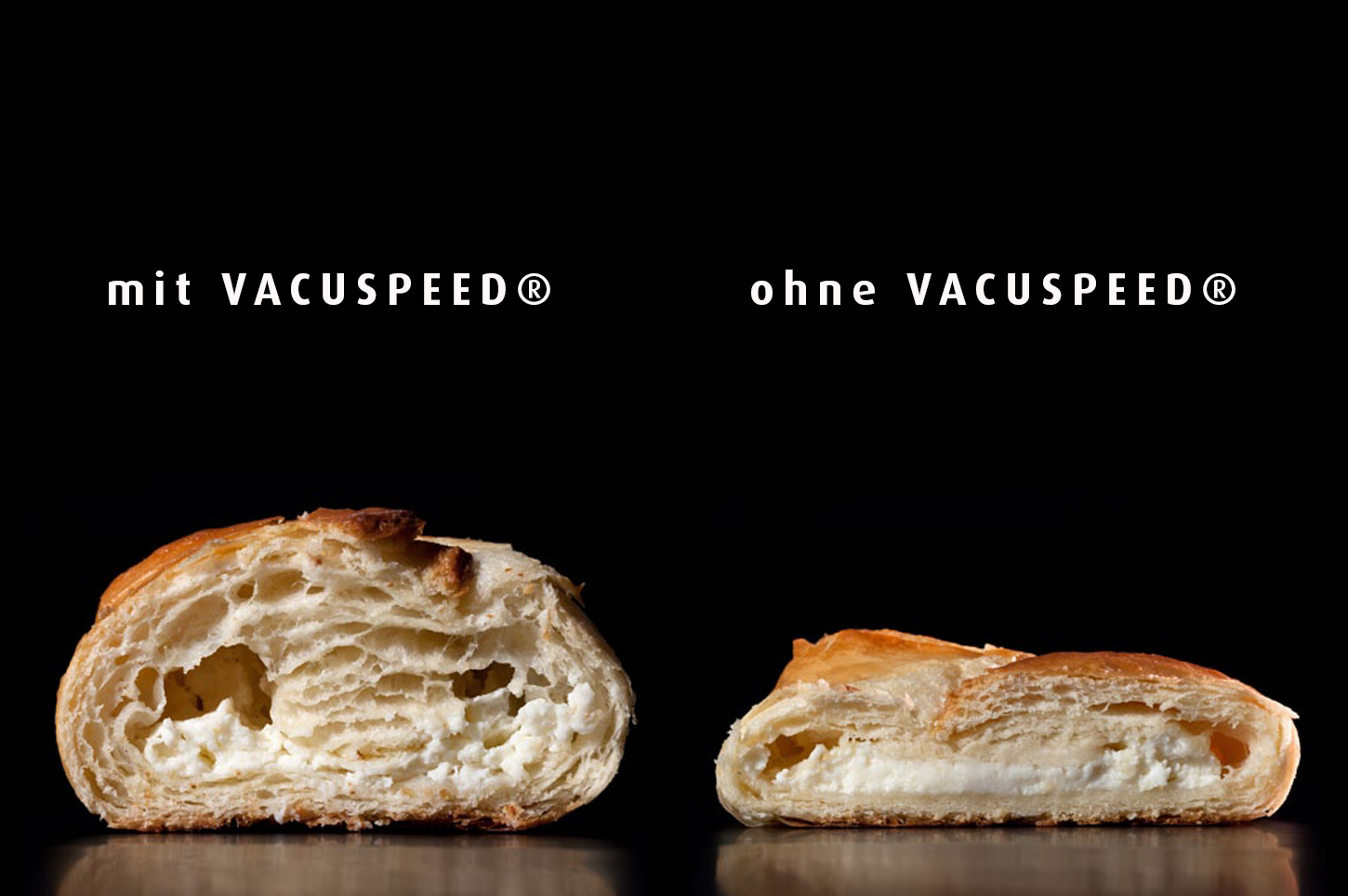

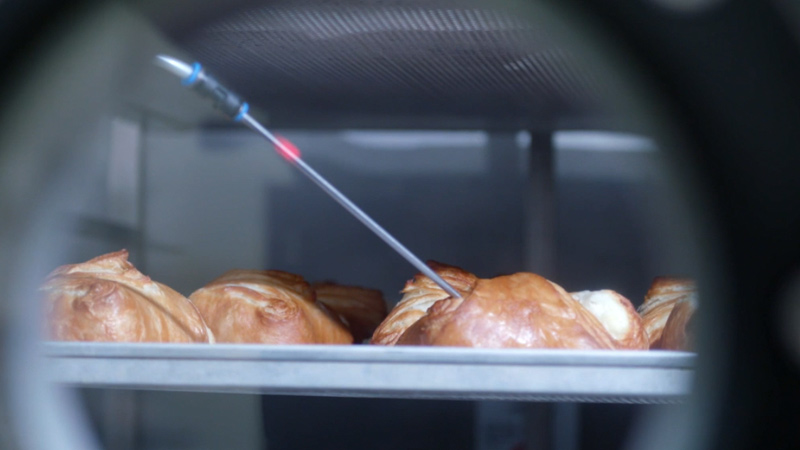

The new “vacuum process” cools baked goods faster than all previously known methods. Oven-hot baked goods are cooled in just a few minutes. Long cooling times are a thing of the past. The cooled products are immediately available for further processing. Cooling baked goods with the VACUSPEED® vacuum cooling system produces lasting crispness and stability in baked goods. The baked goods are relatively independent of changing weather conditions.

Stable volume

With its patented technology, the vacuum cell cools the goods quickly and gently.The result is juicy, stable baked goods of the highest quality.

A low temperature level in a very short time

Oven hot goods are cooled in the vacuum cell in a very short time to a low temperature level and can be processed quickly.

Variations of the VACUSPEED® artisan

VACUSPEED® vacuum cells from WP Bakery Technologies are specially designed to work with rack trolleys. VACUSPEED® cells come with a swing or a sliding door to take in a rack trolley. VACUSPEED® artisan can be integrated manually or as WP VACUUM COOLING modular into fully automatic charging and automation systems of multi-deck and tunnel ovens.

BAKING

After completion of the baking process in a ROTOTHERM® Green rack oven, for example, the rack trolley is manually pushed into the VACUSPEED® vacuum cell. The products are then quickly cooled immediately after baking.

VACUUMCOOLING II

VACUSPEED® with sliding door and integrated pump stand: The door also opens automatically as soon as the relevant process time has been reached. The version with sliding door is more convenient in comparison, there is no need to open and close the door by hand. The sliding door allows greater freedom of movement in front of the unit.

Die 7 besonderen Eigenschaften der WP VACUSPEED®

als Garanten höchster Qualität

ermöglichen eine Optimierung der Produkte:

WP DIFFERENZDRUCKMESSUNG (patentiert)

feinfühlige, programmgestützte Steuerung der Vakuumierung für optimale Qualität bei dickkrustigen und gefüllten Produkten

WP KALTLUFTUMWÄLZUNG

rezeptbezogene Kaltluftumwälzung für softe Produkte mit perfekter Formstabilität und hohem Volumen

WP RÜCKBELÜFTUNG

keimfreie Rückbelüftung mittels spezieller Reinluftfilter für deutlich verlängerte Mindesthaltbarkeit

NEU: WP SOFTCONTROL

(zum Patent angemeldet)

Regelung der Kondensattemperatur für harte oder weiche Krusten aus der Vakuum-Konditionierung

WP RÖSCHEREGULATOR

zur Einstellung des Röschegrades für eine perfekte Kruste von zart-splittrig bis cross-rösch

WP VAKUUM-ERZEUGUNG

zweistufige Pumpentechnik für ein schnelles und vor allem sicheres Abkühlen

WP MATERIAL-QUALITÄT

Verwendung hochlegierter Edelstähle und hoher Wandstärken für eine stabile Bauweise und eine lange Lebensdauer trotz der durch das Vakuum auftretenden hohen Wechselbeanspruchungen

Performance, maximum benefits and modular options

This is a new dimension to cooling oven-hot products: baked goods cool faster whilst making significant energy savings. The products have a longer-lasting crispness; they stay stable longer and can be cut immediately. The minimum shelf life of refrigerated goods is extended by up to three weeks.

- Quality of baked goods:

- Juicy, stable best quality baked goods

- Longer shelf life

- Stable volume

- Independent of weather conditions, long crispness

- Aromatic browning process only in the second baking phase

- Cost-effectiveness:

- Fast cooling of the products ensures time savings in the production process of up to 70%.

- VACUSPEED® taps into enormous energy savings potential compared to conventional cooling

- Storage and transport temperatures of 4–8 °C

- Reduced energy requirement for crisping up products

- Extension of Best-Before Date by up to 3 weeks

- Flexibility in the further processing:

- Responding more precisely to changing consumer trends

- Fast, germ-free packaging

- Faster cutting

VACUSPEED 14.5.10 SI

Rack trolley 640 x 790 x 1.800

for 580 x 780 mm baking tray:

1 trolley lengthwise or 2 trolleys crosswise

Rack trolley 660 x 810 x 1.800

for 600 x 800 mm baking tray:

1 trolley lengthwise or 2 trolleys crosswise

Rack trolley 640 x 990 x 1.800

for 580 x 980 mm baking tray:

1 trolley lengthwise

Rack trolley 660 x 1.010 x 1.800

for 600 x 1.000 mm baking tray:

1 trolley lengthwise

VACUSPEED 26.10 SI

Rack trolley 640 x 790 x 1.800

for 580 x 780 mm baking tray:

3 trolleys lengthwise or 4 trolleys crosswise

Rack trolley 660 x 810 x 1.800

for 600 x 800 mm baking tray:

3 trolleys lengthwise or 3 trolleys crosswise

Rack trolley 640 x 990 x 1.800

for 580 x 980 mm baking tray:

2 trolleys lengthwise

Rack trolley 660 x 1.010 x 1.800

for 600 x 1.000 mm baking tray:

2 trolleys lengthwise

Options

- with swing door and integrated pump stand

- with swing door and external pump stand

- with sliding door and integrated pump stand

- water coolers

For juicy, volume-stable baked goods with crust

Brioches

Slit rolls

Ciabatta rolls

Hamburger buns

Square rolls

Artisan baguettes

Quarktasche

Pastry

Croissant

Soft wheat dough breads

Large Weizenriese wheat breads

Mixed breads

Features

Features

Features

Features

Our sales team will gladly answer all your product-related questions.