Success story:

Taking employees into the future

The Burkard Bakery in Pommersfelden combines authentic craftsmanship with modern technology to reduce employee workloads while preserving the spirit of traditional products, such as the popular Schlossweck (a type of baked goods). Toni Burkard, a ninth-generation baker, relies not only on machinery but also on trust and collaboration. He takes his team on a journey into the future. Humanity, quality, and passion for the baking trade are at the heart of his work.

Product quality as good as handmade

Bakery Burkard successfully differentiates itself from bake-off products

Burkard Bakery operates 11 of its 14 locations beyond supermarkets’ checkout areas. The traditional bakery knows how to differentiate from the bake-off products the supermarkets’ instore bakeries offer: with its own organic grain, sourdough bread with long resting time, and the Schlossweck, a bread roll only Burkard Bakery does. In the past, round-molding was done by hand during production. The Burkard signature product is now produced fully automatically with the WP SELECTA MODULAR bread roll line. “The quality is excellent, we couldn’t have done it better by hand,” comments Toni Burkard enthusiastically.

The Burkard family has been baking in Pommersfelden since 1760, and Toni Burkard is the ninth generation of bakers. Just like his ancestors, he still farms, sowing and harvesting part of the certified organic grain that is processed in the bakery on 30 hectares of land together with his cousin. The 26-year-old, already a master baker and confectioner, is passionate about his work and is currently qualifying as a bread sommelier.

Bäckerei Burkard GmbH in Pommersfelden

Managing Director: Robert Burkard, Gabriele Burkard

Employees: 190, of which 30 in the bakehouse

Branch stores: 14

Products: over 60

Specialties: Organic Bauernlaib bread, organic emmer bread, organic spelt bread, organic rye bread, wood-fired oven bread, rye flatbread, Schlosskruste bread, Schlossweck roll bread

Website: www.baeckerei-burkard.de

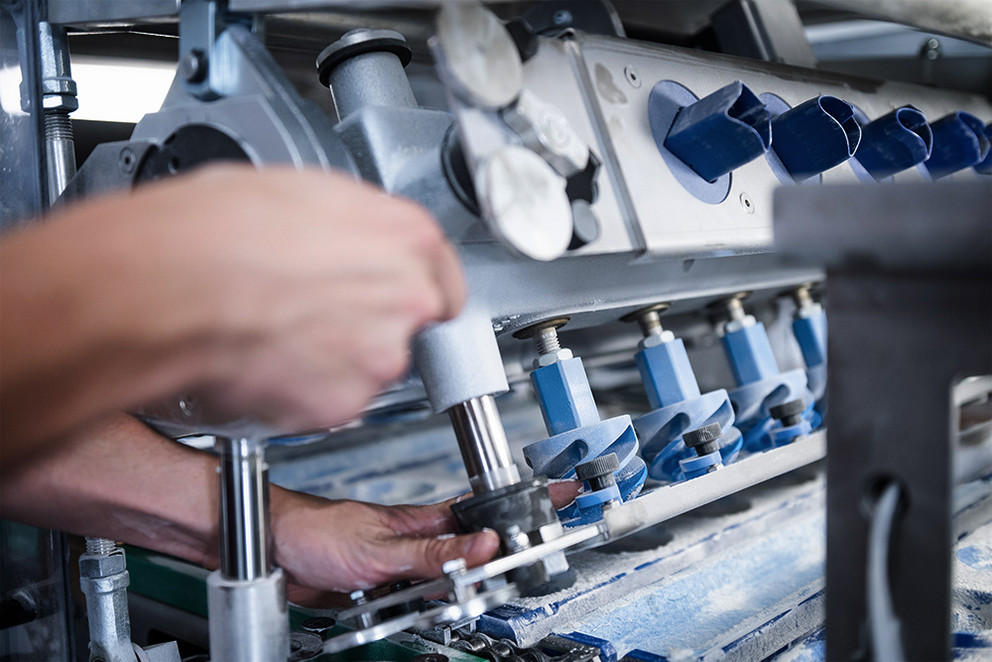

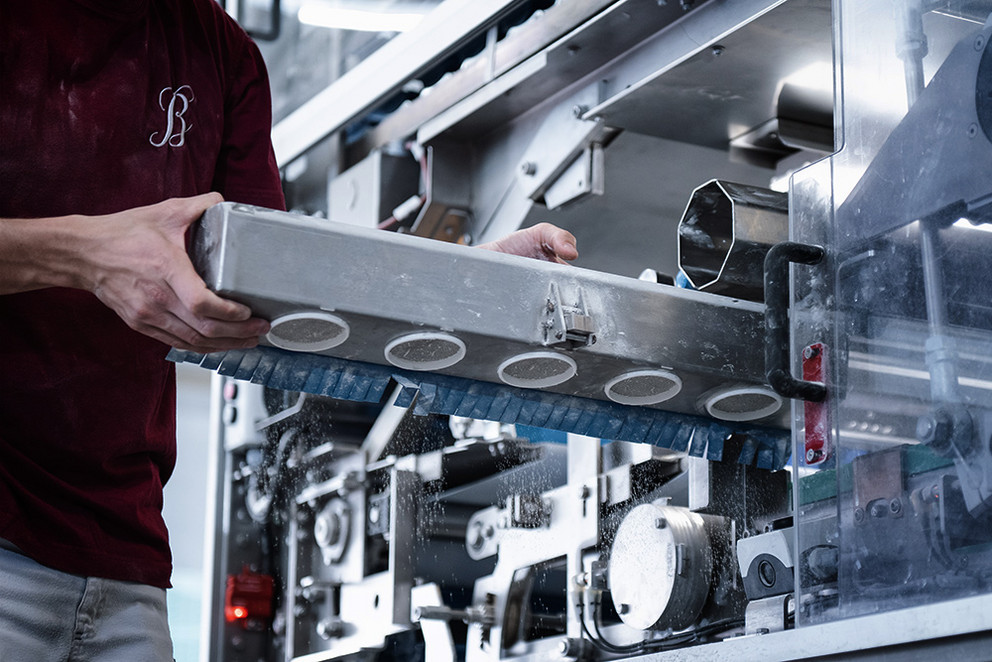

A loading system facilitates the loading of bread into the deck oven. The dough tub is now lifted to the hopper of the dough divider using a lifter, and the entire range of five types of bread rolls is now running on the SELECTA MODULAR roll production line. The dough pieces for the pretzels are also portioned and formed using the line before a pretzel twisting machine takes over the second step.

The family already has a Rollmeister and a Formprofi bread roll production line from Dinkelsbühl in operation. However, the Schlossweck bread roll, the bakery's signature product, could not yet be produced fully automatically and employees still had to do the round-molding by hand. The new line clearly boosts efficiency and facilitates work for employees. However, for Toni Burkard, it is very important that not only he acknowledges this, but also that the employees are involved and kept on board. The more so as most employees are not only older than him in terms of age, but also have many more years of professional experience.

The young master baker and confectioner has literally taken his employees with him – to two trial baking runs with a SELECTA MODULAR at the WP Bakery Technologies baking center in Dinkelsbühl. With their own ingredients, using their own recipe and the corresponding programming by WP's master baker. “I was not sure that this would work out” he says, but the result convinced him.

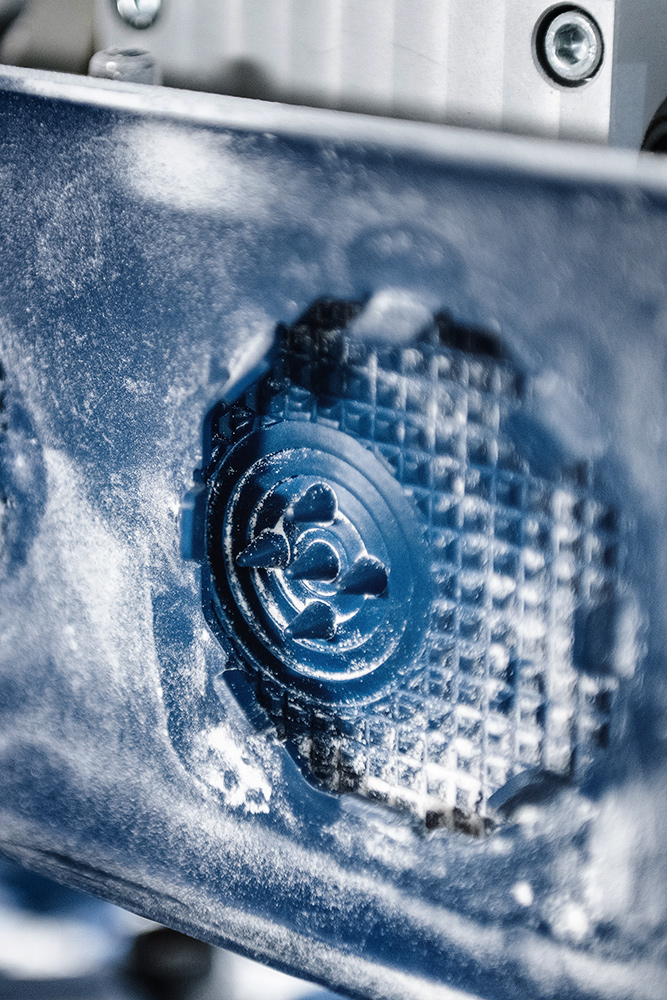

Not only during trial baking in Dinkelsbühl, but also during operation. At peak times, up to 5,200 Schlossweck bread rolls per hour are produced on the line. The Wachau station works flour into the dough pieces particularly gently and carefully. Production is now handled by only one employee instead of two. The round, floured rolls are stored deep-frozen on boards and, like the second bestseller, Kaiser rolls, are actually baked in the branch stores. Burkard Bakery operates 11 of its 14 locations beyond supermarkets’ checkout areas, from Schlüsselfeld in the west to Hirschaid in the east and from Bamberg in the north to Röttenbach in the south.

Interview with Tony Burkard

SELECTA MODULAR KOMBI bread roll line

as a selected configuration for Burkard Bakery

Modules

Basic module, stamping unit with Wachau station, long roller, cutting unit, depositing unit, power cabinet

The highlights

- Hourly output from 3,600 to 9,000 pieces

- Pre-proofing time 8 to 16 minutes

- Revolver stamping head for stamping tools and Wachau station with up to 4 rows of tools, individually expandable through exchange rails

- Variety of modules for long rolling, pressing, folding, etc.

- Green mode/direct depositing possible

- For a maximum level of hygiene: Exchangeable hanger ribbons

- UV degermination

- Maintenance-free ribbon chain

- Attachment of external units possible: Seeding, multi long roller, angle cutting unit, external depositing unit, tray loading robot

- The Wachau station works flour into the dough pieces particularly gently and carefully. This creates the rough surface typical of Wachau rolls.

What’s new?

Stay up to date with the WP newsletter.