MATADOR

Industrial quantity in best craftsmanship quality

Mechanical processing of particularly soft and sticky dough

Perfect round-moulding

The drum moulding system of the TEWIMAT is particularly gentle on the dough. Delicate dough structures are particularly well maintained thanks to the extended moulding time.

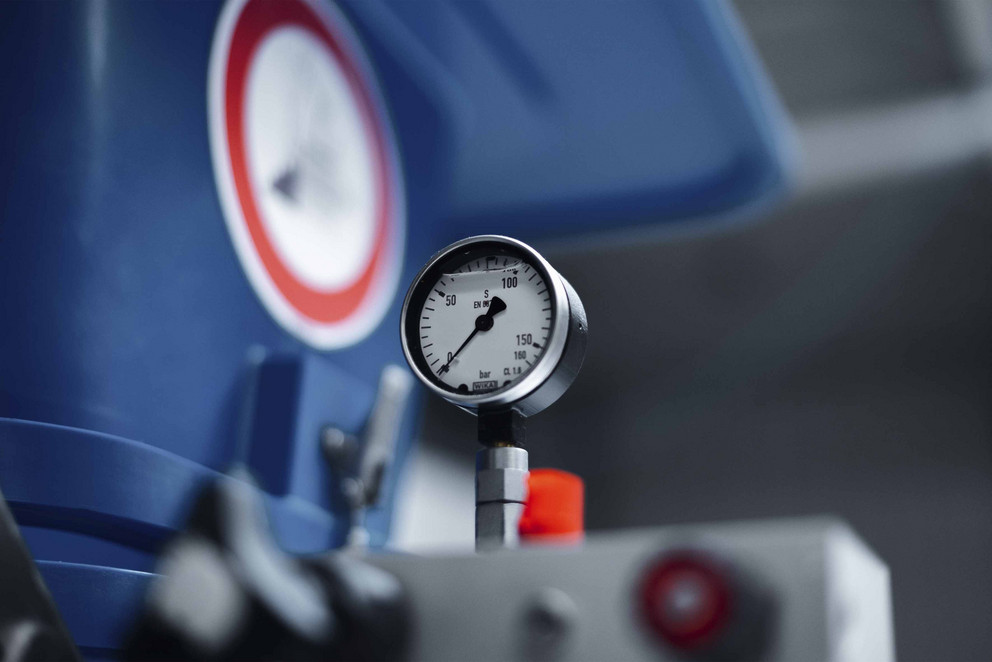

Gentle dividing

Using the proven suction divider principle – as gentle as handmade: Sensitive dough structures are maintained because no feed rollers and dividing knives are used. The pressure of the conveying pistons can be variably adjusted, and ensures maximum gentleness on the dough as well as oil-free operation.

Unlimited variety of products

The double measuring piston technology developed by WP allows maximum flexibility within the weight ranges.

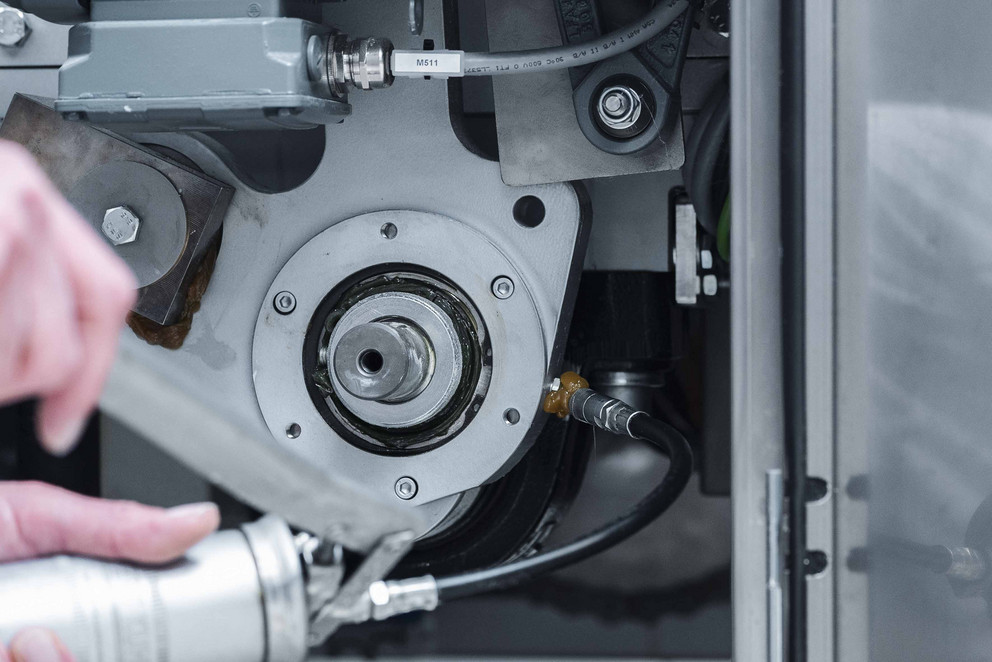

Perfectly cleaned in no time

All dough-handling parts can be removed for the most part without tools, dough-handling parts are consistently separated from the drive mechanism, oil-free dividing process, divided removable cleaning brush, removable driving roller.

Operating status instantly visible

Dough dividers and molding machines equipped with LEDs

All WP dough dividers and molding machines are now equipped with LEDs indicating their status. The LEDs light up in colors Blue, Yellow, Red, and White. The brightness can be set to suit the ambient conditions. The high-intensity LEDs are clearly visible even in bright light. In conjunction with the new door design, the dough dividers and molding machines make eye-catchers in production.

White: in operation

The LED lights up white. Everything in order.

Blue: cleaning operation

The LED lights up blue. The machine is in cleaning operation. Once cleaning is complete and the machine is operational, the LED lights up yellow.

Red: malfunction

The LED lights up red. Operation is disrupted.

Yellow: Ready for operation

The LED lights up yellow. The machine is operational.