MATADOR

No stress and accuracy in weight terms

The new patented dividing system ensures gentle dough processing and weight accuracy at the highest level.

Flexible dividing range

It requires only a few simple steps to adjust the weight range the way you need it for your product idea. This is effortless thanks to the double piston system and the easily replaceable chamber drums.

Typical structures of the bakery items are retained

Thanks to the integrated drum moulder, the exceptionally long moulding path and the adjustable moulding belt flouring.

Flexible in the number of lanes

The MULTIMATIC can be converted in no time by simply turning the measuring pistons. Each lane can be locked independently of the other.

Integrated

drum moulder

- 1- to 5-lane dough dividing and round-moulding machine

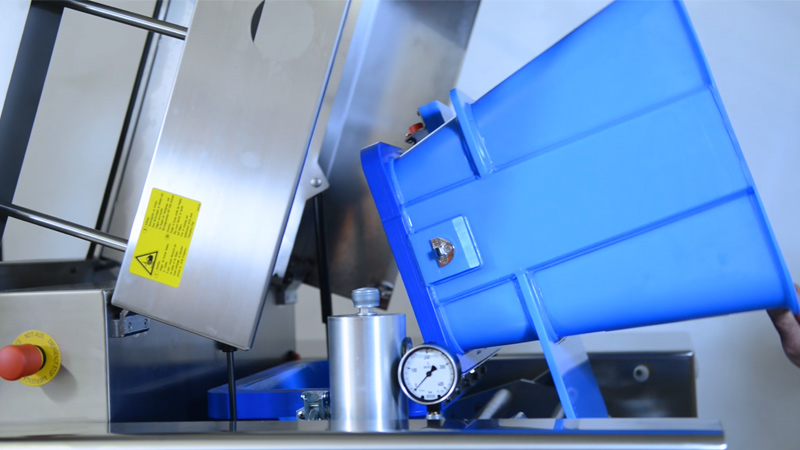

- Foldable plastic hopper in hygienic blue

- Manually adjustable hydraulic pressure, controlled by pressure gauge

- Swivel-mounted, removable flour duster for moulding belt flouring

- Automatic weight adjustment

- Frequency-controlled main and moulding drive

- Divider bed made of wear-resistant material

- Replaceable measuring unit with rotary valve (1-, 3- or 5-lane)

- Standard rectangular pistons in hygienic blue (depending on choice of measuring unit)

- Manual piston locking of each individual piston

- Chamber drum according to size of selected rectangular measuring piston in hygienic blue

- Chamber drum cover with quick-release fastener

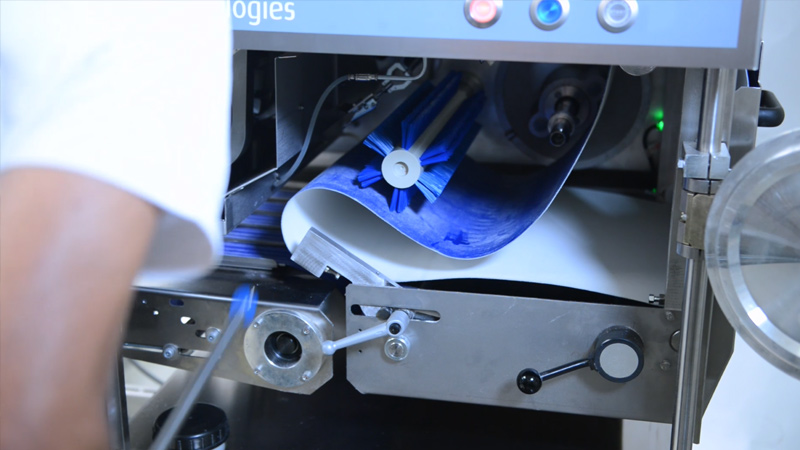

- Grooved moulding drum with cups in hygienic blue

- Moulding belt with plastic/cotton surface, white

- Two automatically approachable cleaning positions

- Conveying piston can be removed without tools

- 900 mm spreading belt, felt design in white, low rim height

- Separation of spreading belt at outlet manually adjustable

- Siemens S7 touch screen control panel

- Exterior housing made of stainless steel

- CE safety design

Operating status instantly visible

Dough dividers and molding machines equipped with LEDs

All WP dough dividers and molding machines are now equipped with LEDs indicating their status. The LEDs light up in colors Blue, Yellow, Red, and White. The brightness can be set to suit the ambient conditions. The high-intensity LEDs are clearly visible even in bright light. In conjunction with the new door design, the dough dividers and molding machines make eye-catchers in production.

White: in operation

The LED lights up white. Everything in order.

Blue: cleaning operation

The LED lights up blue. The machine is in cleaning operation. Once cleaning is complete and the machine is operational, the LED lights up yellow.

Red: malfunction

The LED lights up red. Operation is disrupted.

Yellow: Ready for operation

The LED lights up yellow. The machine is operational.

Consistent hygiene

- Hygienic design

- Elimination of screw joints

- Exterior housing made of stainless steel

- Hygienic design, all dough-handling parts available in hygienic blue

- Freely accessible, most side panels can be opened

- Machine stands on adjustable feet Underside of the machine perfectly accessible

- Two automatically approachable cleaning positions

- All dough-handling parts can be removed for cleaning largely without tools

- Measuring unit can be removed for cleaning

- All dough-handling machine parts are consistently separated from the drive mechanism

- Swivel-mounted, removable flour duster

Hygiene

Hygiene