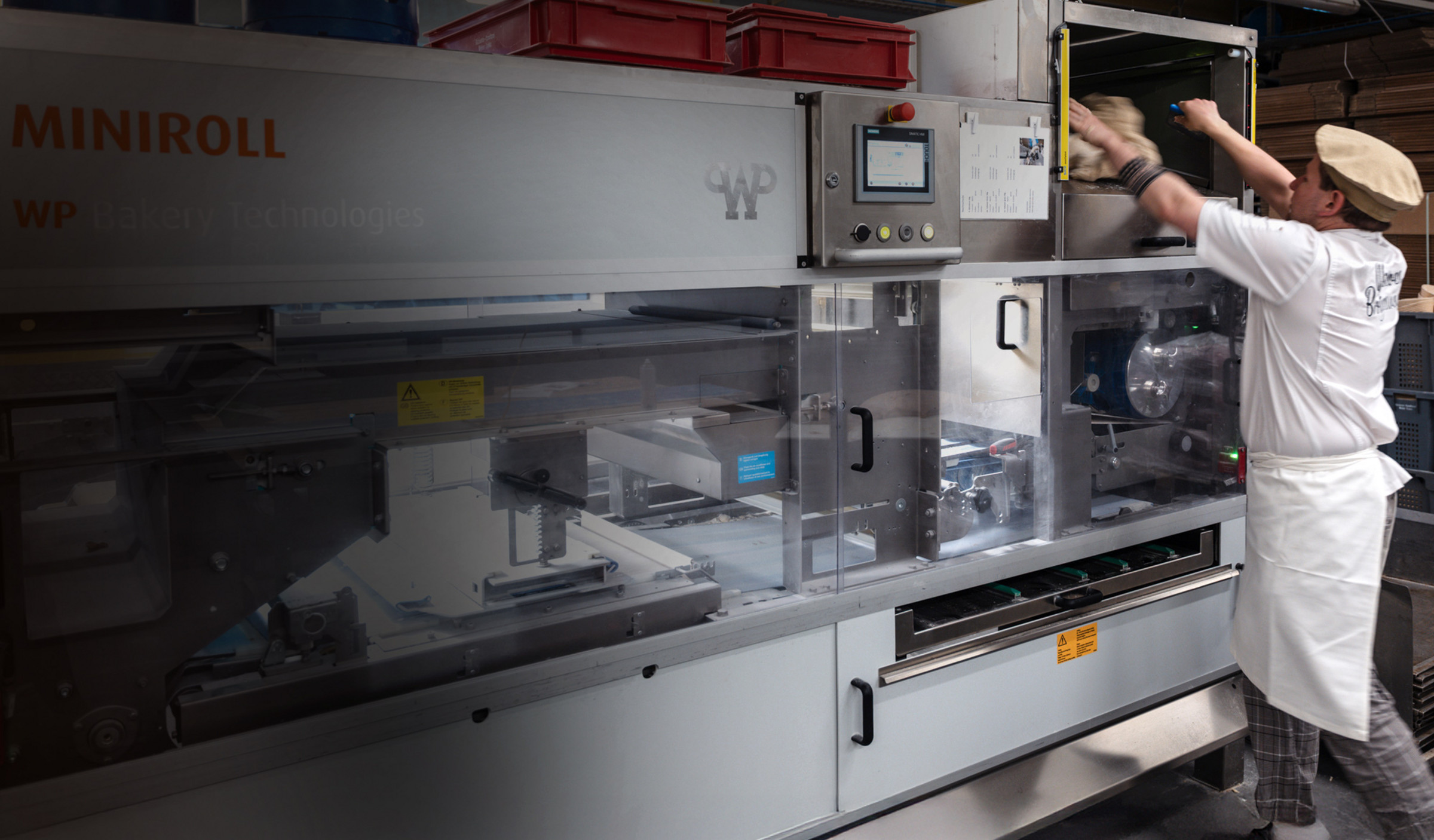

Success story:

Weber Bakery produces

with WP MINIROLL

“Production is optimized to the max in terms of economic efficiency

and organization,” says Rolf Weber, once the bread roll system was

installed in 2024. In the meantime, production has been extended to

include the entire range of bread rolls, small bakery items, and the

brioche bun with MINIROLL.

Top performance at high altitude

Passionate baking in fourth generation and winner of the Baker’s Crown in 2019

In Davos, it is all about delivering top performances at high altitude. This applies not only to winter athletes and speakers at the World Economic Forum, but also to Weber bakery at an altitude of 1,560 m. Weber bakery supplies nearly all 4- and 5-star hotels in Davos, the WEF, demanding customers in the store, and restaurant guests. Rolf Weber, a passionate baker in fourth generation and winner of the Baker’s Crown in 2019, demands nothing less than top performance from himself, his employees, and his suppliers.

Whoever wants to reach the 37-year-old master baker and chef in March, needs a lot of patience and the luck that he likes to talk about things that are in line with his idea of quality and perfection. December to March is high season in Davos. This is when production in the 550-square meter bakehouse at Promenade 148 in Davos runs in two shifts.

Bäckerei-Konditorei-Café Weber AG

Managing Directors: Rolf and Adrian Weber

Employees: up to 45, of which 19 in the bakehouse

Products: over 200

Specialties: Bünden nut gateau, pear bread, panettone, Parsennsteine, URSIN sourdough breads, chocolate-dipped almonds, Zauberberg fruit bread

Awards: first bakery awarded the graubündenVIVA-regio.garantie

Website: www.weber-davos.ch

What a streak of luck that the Miniroll bread roll system was delivered, installed, commissioned, and adjusted to the requirements of very soft dough by Wüst Bäckerei- und Gastrobedarf AG and WP Bakery Technologies within a short time last fall. “Production is optimized to the max in terms of economic efficiency and organization,” says Rolf Weber, once the bread roll system was installed in 2024. In the meantime, production has been extended to include the entire range of bread rolls, small bakery items, and the brioche bun. During high season, up to 14,000 of these pieces are produced per day.

The simple adjustment options and automatic weight regulation of the WP Miniroll render product changes child’s play. “The system makes the work for the staff easier, and we are finished with bread roll production one to two hours sooner,” says Rolf Weber, fully convinced of this investment.

Before, the team around Rolf Weber struggled with a head machine and plenty of manual work to be able to provide the extensive product range and cater to last-minute orders. The range of products includes small baked goods with grammages of 34 to 130 g as well as round and longish shapes. Due to their small grammage, some products could not be produced on another system.

But with the MINIROLL, because the double piston system of the MULTIMATIC head machine allows grammages of 35 to 150 g. Not the only thing that had Rolf Weber convinced of the system during a test with his own dough in the WP Baking Center in Dinkelsbühl. He is fully aware of the importance of the gentlest possible dough dividing and molding process for the quality of the baked goods. The MINIROLL comes equipped with a gentle drum molding system, an adjustable molding belt, and variable molding intensity

“It’s always the result that counts,” knows Rolf Weber. The result of his best-selling signature product for gastronomy and hotel industry had him convinced: the round, 48 grams light Ballon, a golden yellow, and almost round small bakery item made from wheat flour.

And another detail inspired the perfectionist: its weight accuracy. Every dough piece has the same size and grammage.

The MINIROLL is also equipped with lateral discharge. After intermediate proofing, dough pieces are output for further processing into pretzels, bread sticks, or other bakery items. Weber bakery processes very soft dough (yield of 175), which also has the tendency to stick due to the long dough resting time of up to 48 hours. To avoid dough residues on the discharge conveyor belt, it was modified accordingly to meet Rolf Weber’s requirements. “It was really great to see that a solution was found so quickly to make the system a perfect fit for us,” says Rolf Weber, impressed by this passion for perfection.

What’s new?

Stay up to date with the WP newsletter.