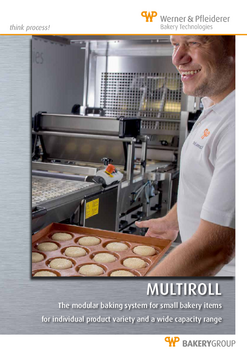

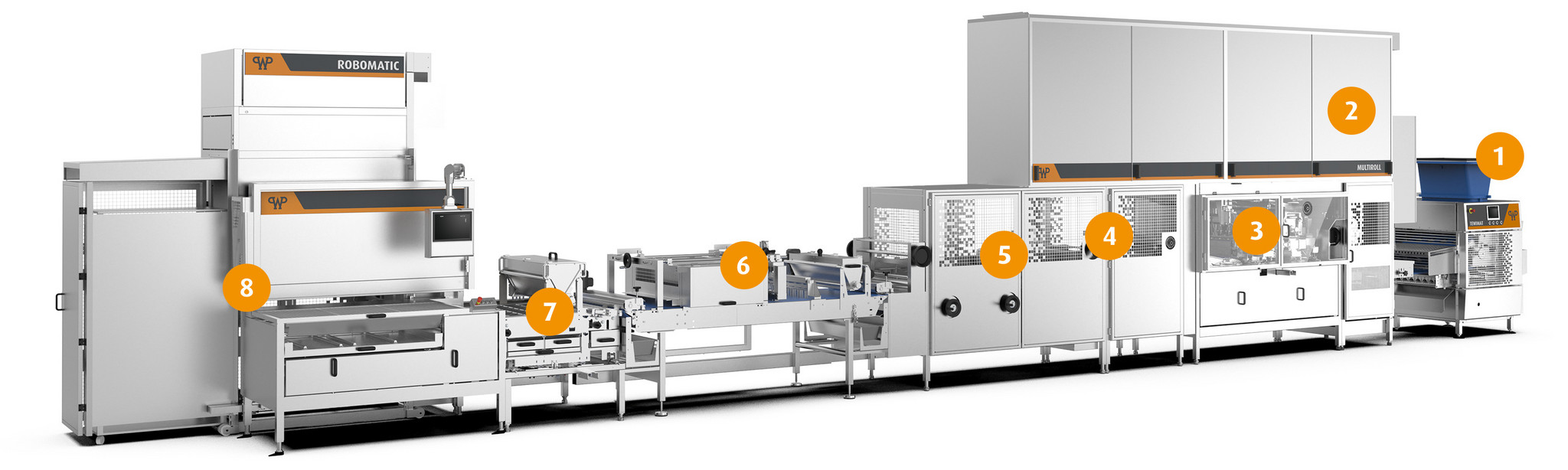

Multifunctional roll line

MULTIROLL

the future-proof bread roll line

The MULTIROLL bread roll line produces a variety of small bakery items with a dough weight of 30 g to 150 g, and even up to 250 g in weight and 28 cm in length using a pre-long roller. Round, long-rolled, flat, stamped, slit, braided, and sprinkled: You specify the products for your range and the required hourly outputs. We take care of the process – for your success.

The modular design of the MULTIROLL bread roll line

offers maximum flexibility and product variety.

The MULTIROLL offers a great number of modules and interchangeable modules for the forming and finishing of small bakery items. Your benefit: a single system, high level of flexibility, excellent product variety.

Dividing and molding (1), and pre-proofing (2)

Individually customizable to suit your preferences

Dividing and molding

think process! Product quality starts with the tried-and-tested dough dividing and round-molding machines from WP. The choice is yours:

MULTIMATIC SERIES

Depending on machine type and configuration

Weight range: 24 g to 600 g

Performance: 400 to 2,000 pieces per hour and row

or

TEWIMAT SERIES

Depending on machine type and configuration

Weight range: 24 g to 600 g

Performance: 1,600 to 3,000 pieces per hour and row

Automatically produced small bakery items like handmade

TEWIMAT and MULTIMATIC guarantee an efficient production of round dough pieces of consistently high quality.

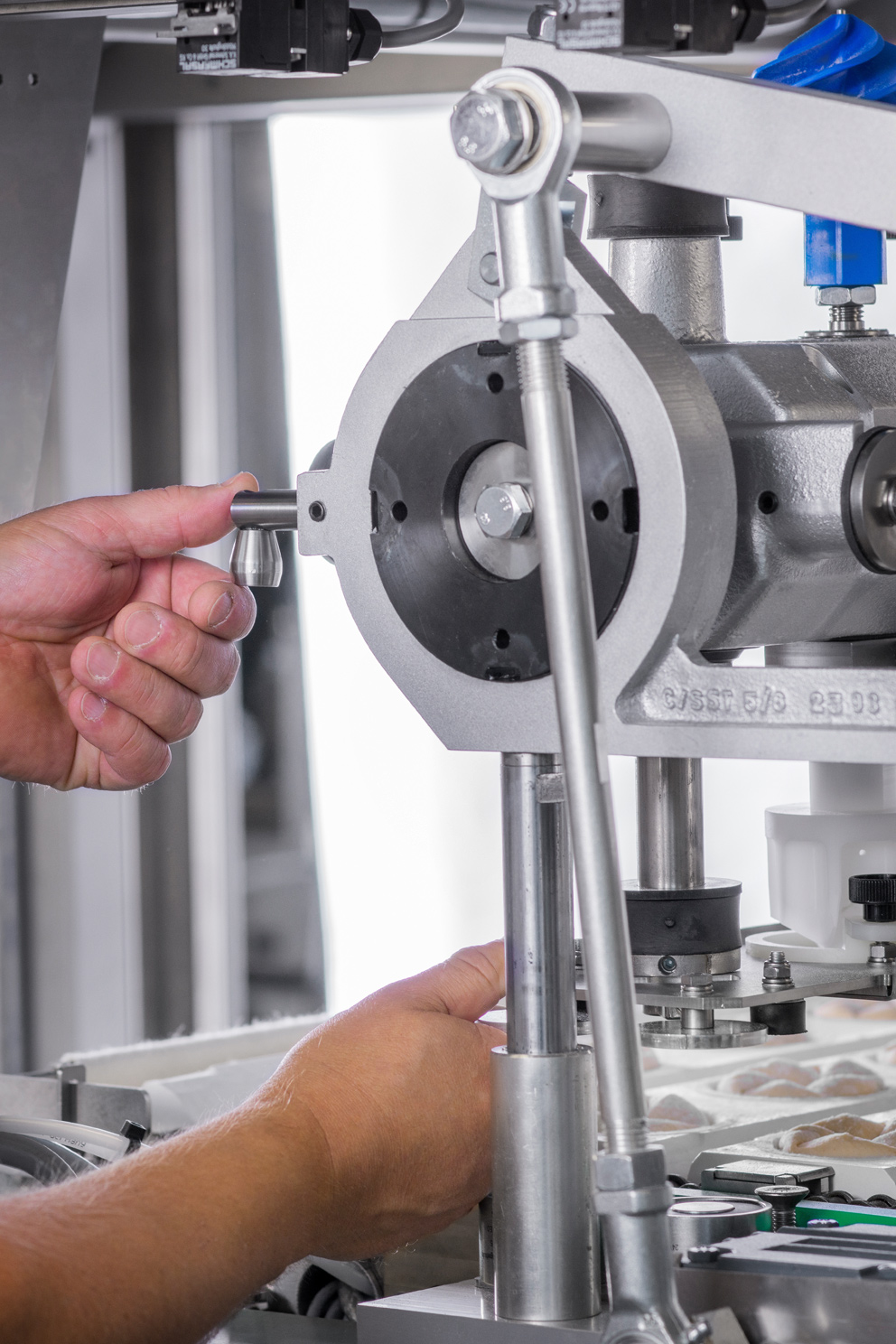

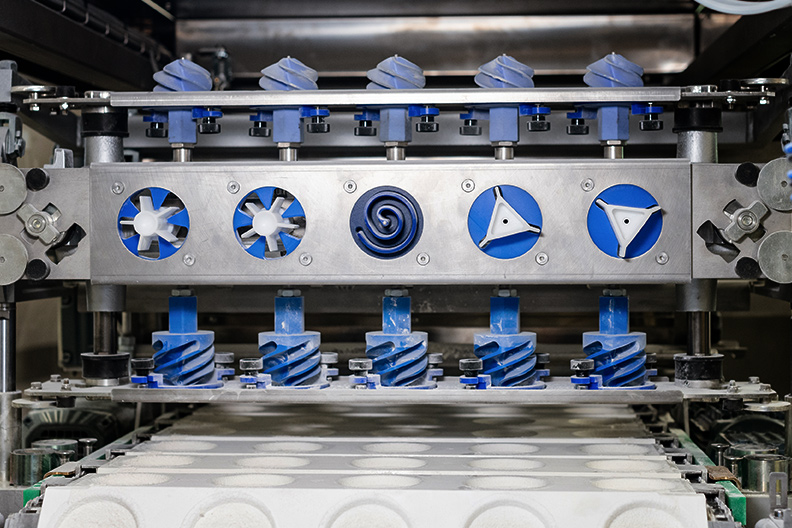

Interchangeable module: Conveyor belt or stamping unit (3)

Stamped rolls in best craftsmanship quality and unlimited variety

The conveyor belt designed as an interchangeable module is used for the downstream transport of higher dough piece weights. As an alternative, the revolver stamping head for stamping tools and a maximum of four rows of tools is used. The stamping patterns can be individually extended using exchange rails. We offer a great selection of tools for stamping patterns. These come either as interchangeable modules with revolver stamping head and exchange rail for quick product change, or are permanently installed in the system.

The revolver stamping head for stamping tools

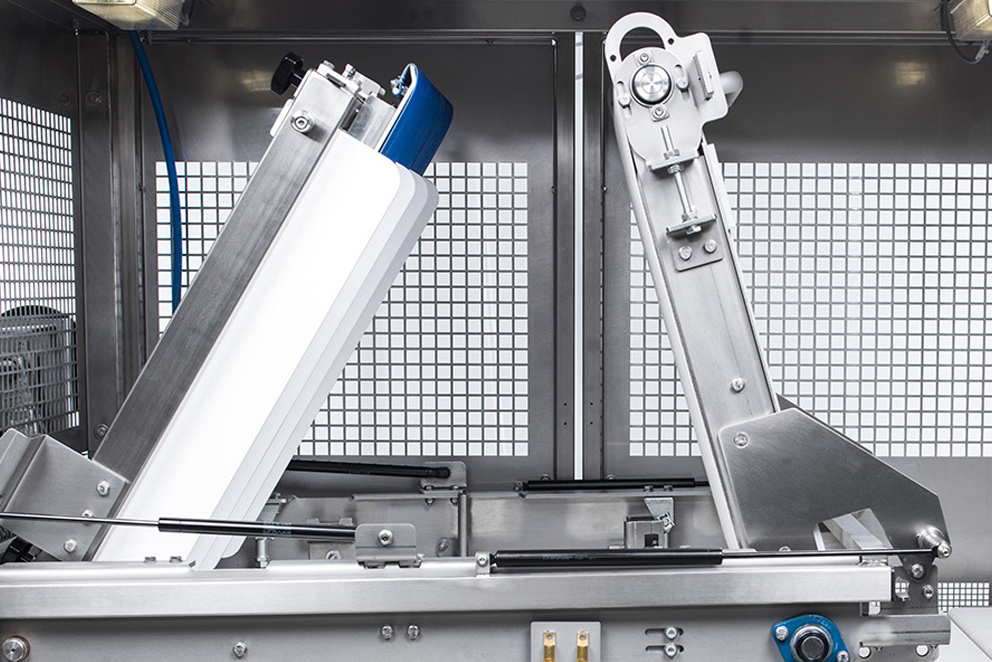

Module: High-speed roller (4)

Combined high-performance braiding and long rolling module

Stamping in all shapes and forms, long rolling, angle and diagonal cutting? Other small bakery items lines can manage all that as well. But how about high-performance braiding and long rolling? The new WP MULTIROLL high-speed roller produces items in a weight range of 30 g to 150 g: flattened, long-rolled (up to 28 cm), and braided products of up to six layers. All that at an hourly output rate of up to 2,760 pieces per hour and row, if required.

Roller module combined with long-roller module

for braided products such as Kornspitz.

Module: Multi long roller (5)

Long roller combined with top belt long roller or pressure board long roller. Interchangeable pressure boards for:

Flattened products

![[Translate to Englisch:] Druckbrett für flachgedruckte Produkte Pressure board for flattened products - Flattening of dough pieces for flattened products](/fileadmin/wpl/produktwelt/multiroll/WP-Broetchenanlage-MULTIROLL-Druckbrett.jpg)

Interchangeable module: Stamping on belt, longitudinal or angle cutting on belt (6)

Stamping on belt

Weight range: 40 g to 150 g

No. of rows: 4- to 6-row

Hourly output: max. 1,640 pieces per hour and row

Longitudinal cutting on belt

Weight range: 40 g to 150 g

No. of rows: 6-row, depending on working width and weight range

Hourly output: max. 2,000 pieces per hour and row

Angle cutting on belt

![[Translate to Englisch:] Schräg schneiden auf Band WP bread roll line MULTIROLL - Diagonal cutting on conveyor belt](/fileadmin/wpl/produktwelt/multiroll/WP-Broetchenanlage-MULTIROLL-Schraegschneiden-auf-Band.jpg)

Moistening and seeding

![[Translate to Englisch:] Modul Befeuchten und Bestreuen Moistening and seeding module - Prepared dough pieces are moistened and then seeded with grains](/fileadmin/wpl/produktwelt/multiroll/WP-Broetchenanlage-MULTIROLL-Befeuchten-und-Bestreuen.jpg)

Options: Manually controlled or automatic depositing (8)

Dough piece depositing for further processing

The modular system offers a host of depositing possibilities:

- Manual pick-up via drawer

- Automated proofing tray handling with depositing in rack trolleys

- Automated downstream transport of the dough pieces

Automated proofing tray handling with depositing in rack trolleys

Automated tray pick-up handled by the WP Robomatic. The loading system can transport borderless trays, trays with two or three borders, or proofing boards. think process! Take us at our word.

![[Translate to Englisch:] Automatisiertes Ablegen der Teiglinge Automated depositing of the dough pieces](/fileadmin/wpl/produktwelt/multiroll/WP-Broetchenanlage-MULTIROLL-Ablage.jpg)

Easy to operate, freely programmable,

perfect visibility at all time

Large touch display

Easy operation

Master control

password protected

Depositing unit

freely programmable

Remote maintenance

Networking and efficient remote diagnosis as well as remote maintenance possible. Data backup to flash card or USB flash drive.

Siemens touch control

Easy to operate, freely programmable, perfect visibility at all time.

WP DIGITAL PORTAL: Register now!

Safeguarding process quality, boosting efficiency, cutting costs. Take the first step, sign up to the WP DIGITAL PORTAL for free, and register your ovens and machines. The WP DIGITAL PORTAL grants access to machine and system information as well as service functionalities in the web browser. The future is digital!

Hygienic safety

A clean affair!

Hygiene starts with the design of machine and system. Easy to clean or removable components, smart solutions and innovative materials ensure a maximum level of hygiene!

Hygienic safety

Shortest cleaning time

Maximum value retention

- Guide plates, casing, climate modules, long rolling and stamping tools, flour duster and exchangeable modules are easy to mount and remove

- All dough-handling parts and all plastic components in hygienic design version

- High ground clearance to facilitate cleaning

- Window on both sides can be opened and removed

Sieberer Bakery: Tradition meets technology

Christian Sieberer is master baker and confectioner by passion, can also handle a screwdriver and wrench, and has acquired great expertise in production planning and control. As general partner of Sieberer KG, located in Filzmoos, Austria, he knows the market, understands its costs and knows exactly how to optimally exploit the advantages of the WP MULTIROLL baking system for small bakery items for the Sieberer product range.

Success story

The most diverse product range in best quality.

To ensure your product range is appealing and competitive at all times.

Kaiser roll

Slit rolls

Ball donut

Pretzel

Kringel roll

Bread stick

Wachauer roll

Plaits

Kornspitz

Angle cutted baguette

Krentenbollen

Roundmoulded rolls

Stamped rolls

Stamped rolls

Hamburger buns

Kringel bestreut

Button roll

Dinner roll

Raisin rolls

Service and support

We make sure that your production lines run.

WP SERVICELINE

The WP SERVICELINE 24 is our guaranteed connection to the WP SERVICE and outside our opening hours to our emergency service:

Deutschland: +49 800 5 777 123

International: +49 1805 777 123

E-Mail: serviceline@wpbakeryservice.de

Contact us

Any questions? We take care.

+49 9851 905-0

Greater variety in the product range, yet more flexibility and efficiency: The modular design of the WP MULTIROLL combines these seemingly contradictory requirements in a single bread roll line. As much individuality as possible, and as much standardization of the tried and tested as necessary.

A baking system for small bakery items means a substantial investment. It therefore needs to perfectly match your operation and your product range. With its modular approach, the system helps reduce time and effort that need to be invested in production planning, installation, and commissioning. We would be happy to advise you, pour in all our expertise, and find the perfect solution for you to achieve your goals.

![[Translate to Englisch:] Brötchenanlage MULTIROLL Stüpfelmodul MULTIROLL stamping module - Dumping the dough pieces from the stamping cups onto the conveyor belt](/fileadmin/wpl/produktwelt/multiroll/gallery/WP-Broetchenanlage-MULTIROLL-Stuepfelmodul-1.jpg)

![[Translate to Englisch:] Brötchenanlage MULTIROLL High Speed Wickler MULTIROLL high-speed roller - multiple rolling of dough pieces, for example for the Kornpitz](/fileadmin/wpl/produktwelt/multiroll/gallery/WP-Broetchenanlage-MULTIROLL-Modul-High-Speed-Wickler-2.jpg)

![[Translate to Englisch:] Brötchenanlage MULTIROLL mit Fontaine- oder Sprühsystem MULTIROLL bread roll system with fountain or spray system](/fileadmin/wpl/produktwelt/multiroll/gallery/WP-Broetchenanlage-MULTIROLL-Befeuchten.jpg)

![[Translate to Englisch:] Brötchenanlage MULTIROLL Kornspitz MULTIROLL bread roll line Kornspitz - prepared Kornspitz dough pieces on the tray](/fileadmin/wpl/produktwelt/multiroll/gallery/WP-Broetchenanlage-MULTIROLL-Bestreuen-1.jpg)

![[Translate to Englisch:] Brötchenanlage MULTIROLL Transport von Kornspitz Teiglingen MULTIROLL bread roll line transport of Kornspitz dough pieces](/fileadmin/wpl/produktwelt/multiroll/gallery/WP-Broetchenanlage-MULTIROLL-kornspitz-auf-dem-Stikkenwagen.jpg)