Vacuumcooler

VACUSPEED®

industrial

automation system with integrated

vacuumcooling

- Minimal moisture loss

- Energy efficiency through optimal, fully automatic process control

- Flexible Product range

VACUSPEED® the key

to economic efficiency

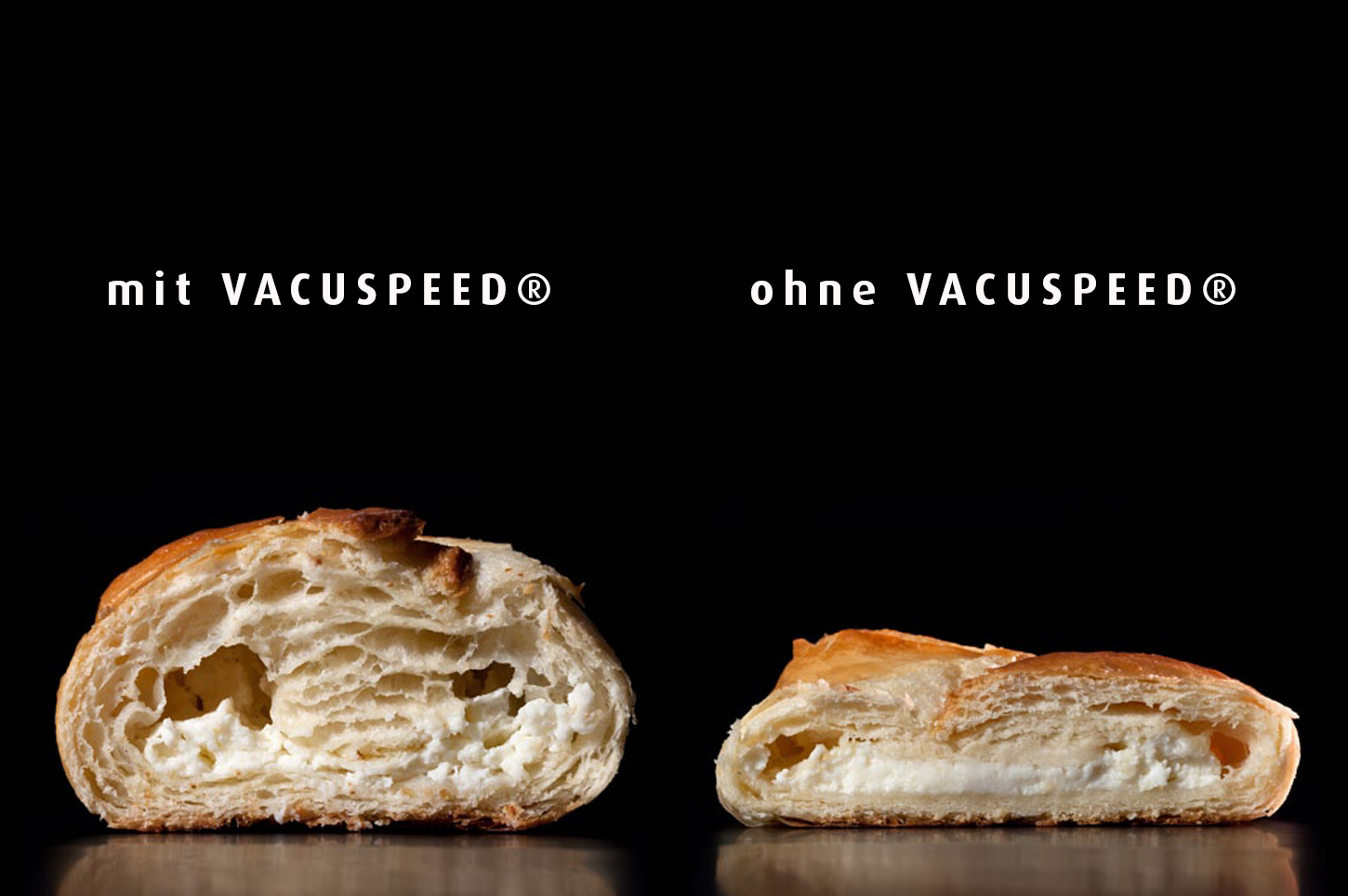

The new “vacuum process” cools baked goods faster than all previously known methods. Oven-hot baked goods are cooled in just a few minutes. Long cooling times are a thing of the past. The cooled products are immediately available for further processing. Cooling baked goods with the VACUSPEED® vacuum cooling system produces lasting crispness and stability in baked goods. The baked goods are relatively independent of changing weather conditions.

Stable volume

With its patented technology, the vacuum cell cools the goods quickly and gently.The result is juicy, stable baked goods of the highest quality.

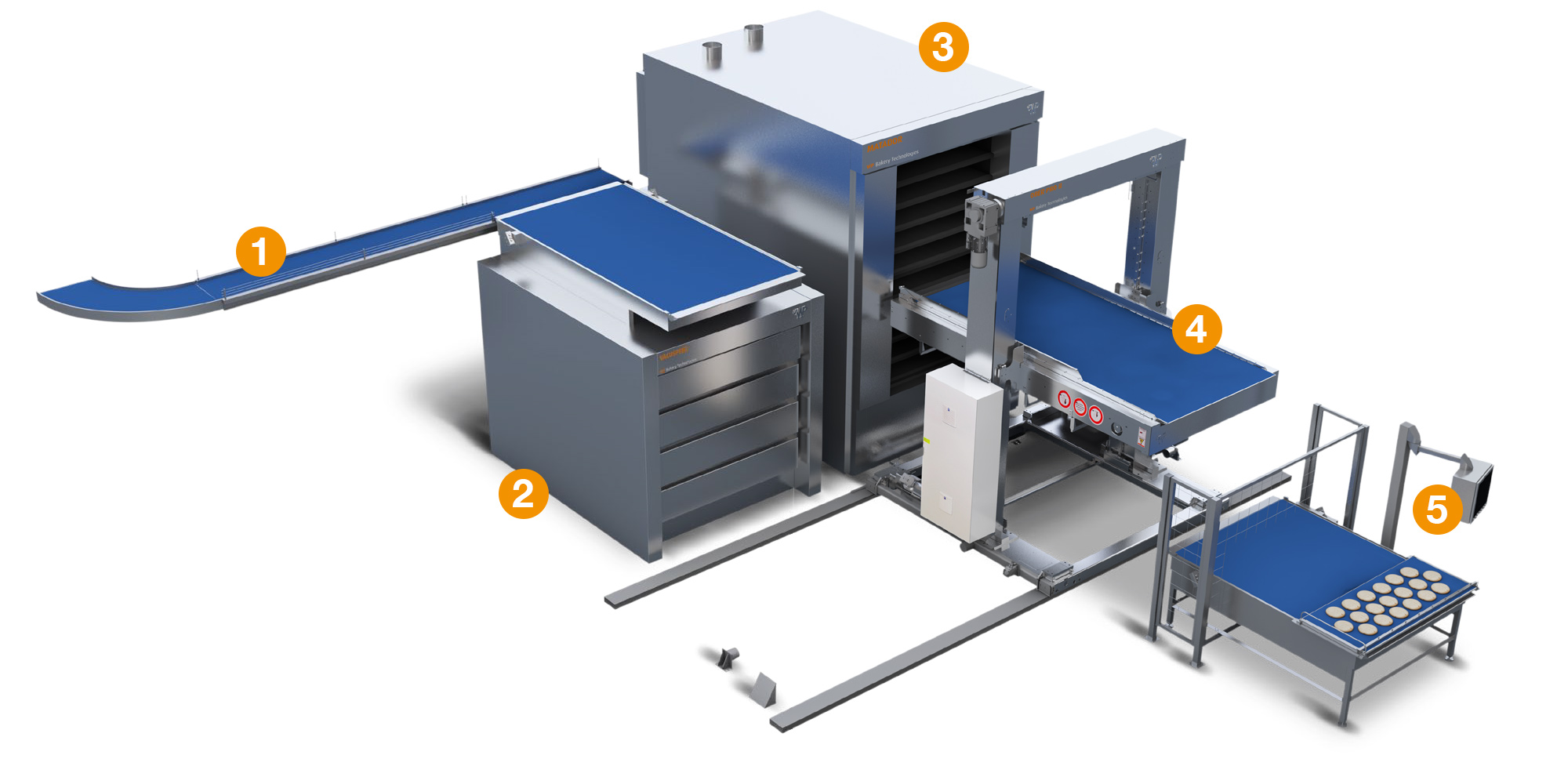

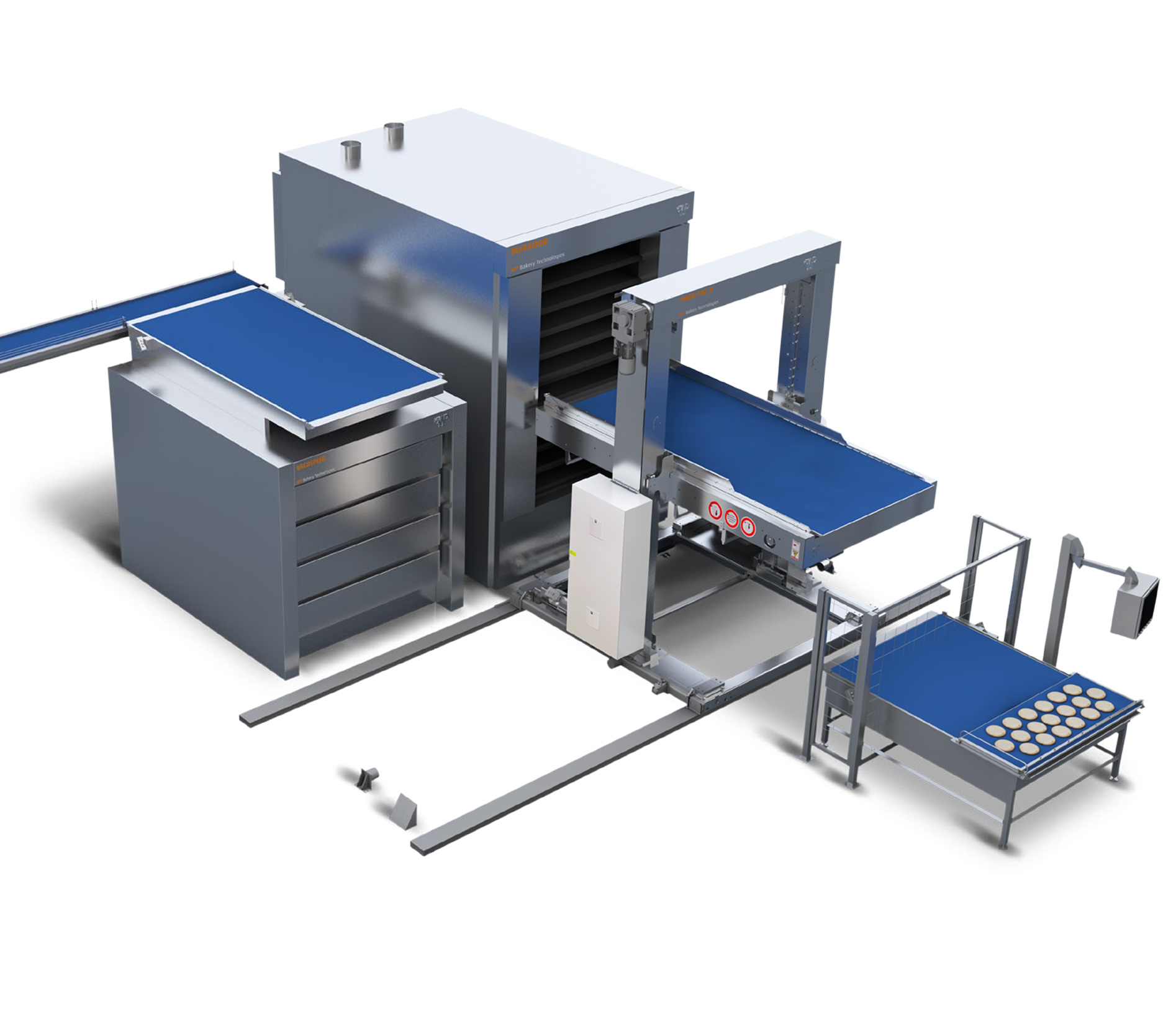

The fully automated feeding and

automation system with VACUSPEED®

The fully automated feeding and automation system has a modular design with integrated vacuumcooling. It is equipped with three optimally matched WP components and is suitable for a wide variety of system architectures. Multi-deck or tunnel ovens can also be equipped with the OBER® PRO II feeding system and high-efficiency VACUSPEED® cooling. Automatic loading and unloading of the stationary cell body by the OBER® PRO II has several major advantages. The solution avoids expensive and vulnerable mechanics in the vacuum system itself. The products are quickly cooled in the VACUSPEED® vacuum cell immediately after baking.

Performance, maximum benefits and modular options

- Quality of baked goods:

- Juicy, stable best quality baked goods

- top-quality craftsmanship with proven WP ZYKLOTHERM® flagstone oven technology

- flexible Product range, 100 % reproducible results

- longer shelf life

- Cost-effectiveness:

- integrated, intelligent loading and unloading control

- Energy efficiency through optimal, fully automatic process control

- Production reliability with WP OVEN-CONTROL, remote diagnostics and BLUE VALUE

- Compact modular build takes up less space

- Optimal capacity utilization of the OBER® Line

- Flexibility:

- Rationalisation and easier working conditions with less heavy lifting

- Easy handling

- 24/7 production of chilled, durable products

Hourly output

1.5 tons / h

(Capacity depending on product size and process time)

Options

(Further options on request)

For juicy, volume-stable baked goods with crust

Brioches

Slit rolls

Ciabatta rolls

Hamburger buns

Square rolls

Artisan baguettes

Quarktasche

Pastry

Croissant

Soft wheat dough breads

Large Weizenriese wheat breads

Mixed breads

Our sales team will gladly answer all your product-related questions.